Sheet metal chamfering machine RITM Industry

Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge is made up of a flat edge meeting a 45-degree angle. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance.

Metabo Bevelling Tool Kfm 93 Rf 110v, 900w Metal Chamfer 45° from Westcountry Machinery 4 Wood

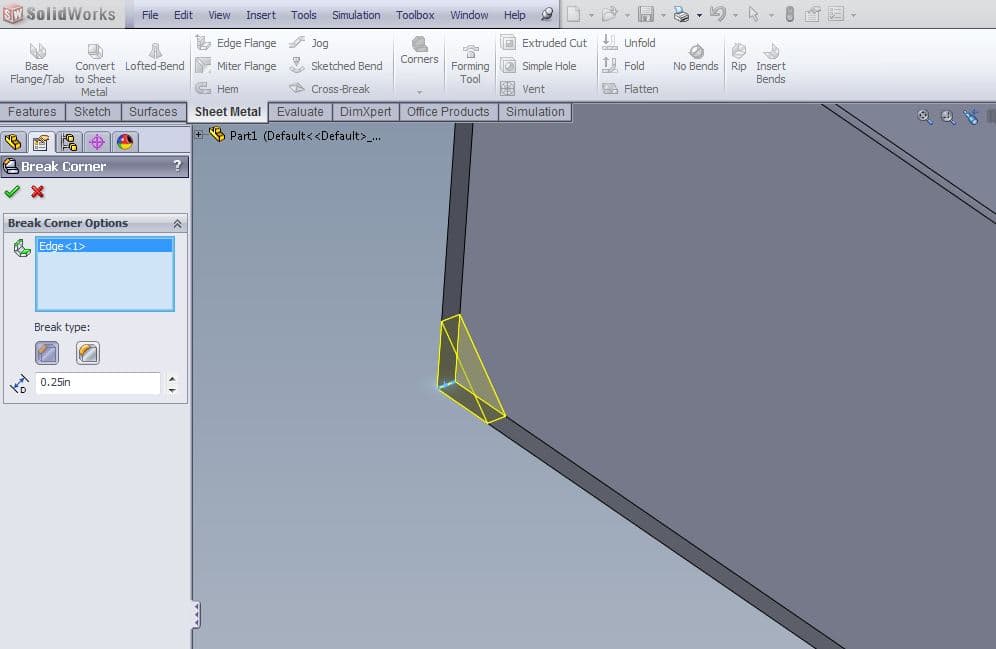

Use Fillet and Chamfer to soften sheet metal edges, if necessary. Be aware that selecting a sheet metal edge must be done at the very corner and not an adjacent edge. Note that advanced Fillet and Chamfer features (conic fillet for example) are not available on sheet metal at this time.

Chamfering metal chamfer metal YouTube

electric chamfering machine BM-20plus. portable for sheet metal for pipe ends. Power: 1,800, 1,600 W. Rotational speed: 2,740 rpm - 3,340 rpm. Chamfer width : 0 mm - 21 mm. BM-20plus is an easy-to-use, portable heavy-duty machine designed for beveling steel plates and pipes prior to welding. The machine is fitted with two rotary milling.

Solved Inventor Sheet Metal Automatic Corner Chamfer On Surfaces With Uneven Angles Autodesk

Chamfering metal with Beveltools bevel heads provides a consistent and accurate angle on sheet material or the outside/inner diameter of pipes. Making a bevel with grinding discs takes too much time and the results are not always as perfect as you would like. The bevel cutters from Beveltools make a smooth beveled edge in one pass.

Shop PVC Chamfer & PVC Products Online 800Benaa Online Hardware Store

electric chamfering machine BM-20plus. portable for sheet metal for pipe ends. Power: 1,800, 1,600 W. Rotational speed: 2,740 rpm - 3,340 rpm. Chamfer width : 0 mm - 21 mm. BM-20plus is an easy-to-use, portable heavy-duty machine designed for beveling steel plates and pipes prior to welding.

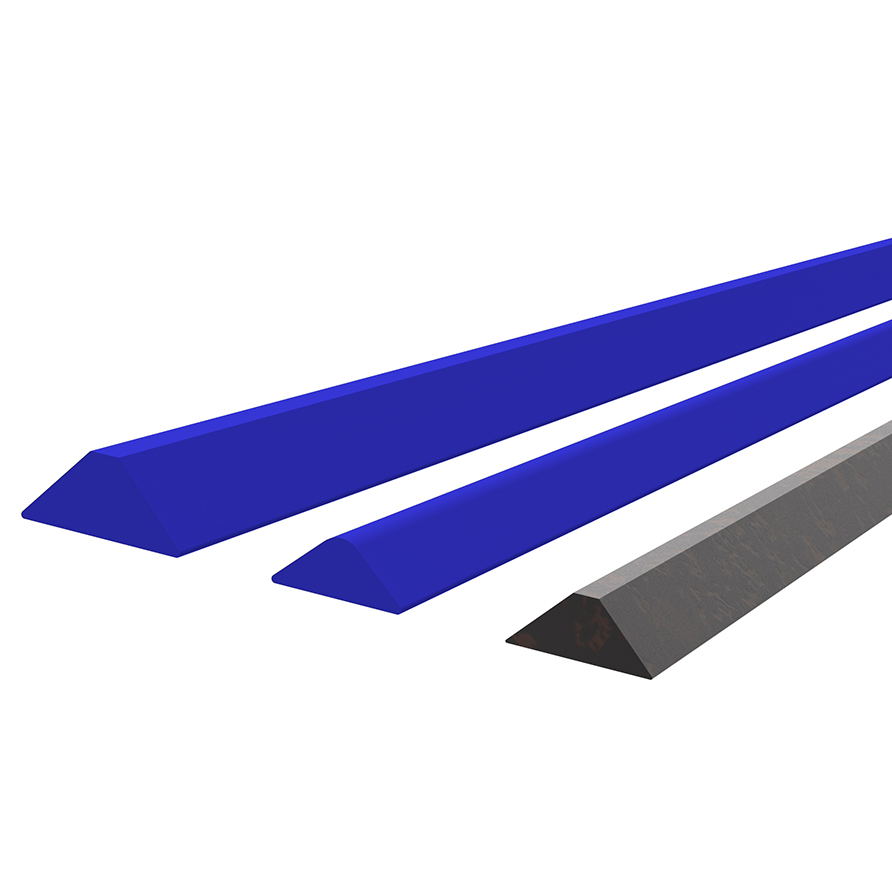

Steel Chamfer Strip By HSMAG

Tech Tips Fillets vs. Chamfers: How to Handle Edges and Corners in CNC Machining Design Posted On May 16, 2022 By Protolabs The crisp, sharp edges in 3D models don't always translate well to the real world and real-world objects. Rounded corners and edges are easier on the eyes, according to experts.

SOLIDWORKS Convert Chamfer to Fillet now available in the 2017 release

Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. Either can eliminate what would be sharp and raw or semi-raw cut metal corners and replace them with either a rounded corner—a radius—or an angled or beveled corner—a chamfer.

China Steel Chamfer Strip/Steel Chamfer China Chamfer, Steel Chamfer

Chamfering metal | chamfer metal Ultimate Handyman 507K subscribers Subscribe 33K views 9 years ago Metal often has a sharp edge when cut which is not desirable, this can easily be removed.

Sheetmetal Chamfer in SolidWorks Computer Aided Technology

When applying a chamfer to sheet metal, you might have to select the exact corner (not an adjacent edge). You can select any combination of edges on parts, and corners on sheet metal. For more information on using Fillet and Chamfer tools with sheet metal, see Sheet Metal Model. Select a measurement type for non-planar adjacent faces.

Nexus Construction Systems Chamfer

SHEET METAL DESIGN GUIDE. 2. Chamfering is a feature whereby the sharpest corners are rounded o˜ to prevent catching, snagging or injury. Chamfers at corners and beads on bends increase the sti˜ness. CHAMFERS Collars increase the sti˜ness around pierced areas such as holes and slots. Coining and embossing around ˚ared holes improve.

Electric chamfering machine / portable / sheet metal / plate EDGE 46 G.B.C. INDUSTRIAL TOOLS

COGT2164 Mechanical Design with InventorWorking with Sheet Metal Components.

Aluminium Edge 2000mm 8.6 x 19.6 x 1.6mm IronmongeryDirect Same Day Despatch

Step 3. Click on the sheet metal edge from which the chamfer will be angled. Step 4. Click on one or both corners of the sheet metal edge to apply the chamfer. Note that you can select only sheet metal edges and model edges that represent corners. Step 5. In the "Distance" and "Angle" drop-down lists, specify the desired chamfer distance and angle.

Metabo Bevelling Tool Kfm 93 Rf 110v, 900w Metal Chamfer 45° from Westcountry Machinery 4 Wood

On the ribbon, click Sheet Metal tab Modify panel Corner Chamfer . Click Distance and Angle. Click the sheet metal edge the chamfer is angled from, and then click one or both corners on the sheet metal edge. You can select only sheet metal edges and model edges representing corners. In the Distance and Angles drop-down lists, specify a chamfer.

METAL REMOVAL Carbide Chamfer Mill 1/4″ 2FL 90° M30152 Dan's Discount Tools

Position the cutter centrally over the drilled hole, with the cutter rotating, and move axially to flange depth (Z = flange height - chamfer size) Feed the cutter to engage with the radius compensation (Y = hole radius) Interpolate 360. Feed back to hole centre. Retract cutter.

Chamfer Rod for Gouging and Cutting

Outside Chamfer End Millsfor Pipes, Tubes, and Rods. Mill an angled edge to the entire outside diameter of pipe, tubes, and rods in a single pass with more speed and precision than a handheld scraper. These end mills deburr pipe and tube for butt welds and shape rods for sliding into housings and holes.

Electric chamfering machine GTW2700 Daesunggt co.,Ltd handheld / sheet metal / for sheet

Document filed by International Association of Sheet Metal, Air, Rail and Transportation Workers' Local Union No. 28, AFL-CIO, Sheet Metal Workers' Local Union No. 28 Annuity Fund, Sheet Metal Workers' Local Union No. 28 Assessments Fund, Sheet Metal Workers' Local Union No. 28 Building Fund, Sheet Metal Workers' Local Union No. 28 Education.